How to use the DRYIT semi-continuous tray dryer

Practical Action

Which route then should an intending user chose? No hard and fast rules can be applied, as

much will depend on the crop and local situation. The following points however should be

carefully considered:

Are fuel costs a major concern? In some cases the cost of fuel is only a very small

percentage of total cost. In such cases time and money might be better spent on

better packaging or advertising.

Is the product of very high value? Here over drying would reduce profits as less water

is being sold with the product. Quality may also be lower.

Is the product very sensitive to heat? Spices and medicinal plants for example

may loose more of the active, sensitive components if batch dried.

Local labour costs and social attitudes. Does shift work involve a very high bonus for

example or are workers unlikely to want to work nights?

Most users process a range of products rather than just one type of crop or food. Therefore a

semi-continuous dryer is recommended, because it can also be used as a batch dryer and

therefore provides the most flexibility. For business purposes, the DRYIT dryer provides an

ideal starting point. DRYIT is medium size and semi continuous, ideal for flexibility and

experimentations when starting a drying business.

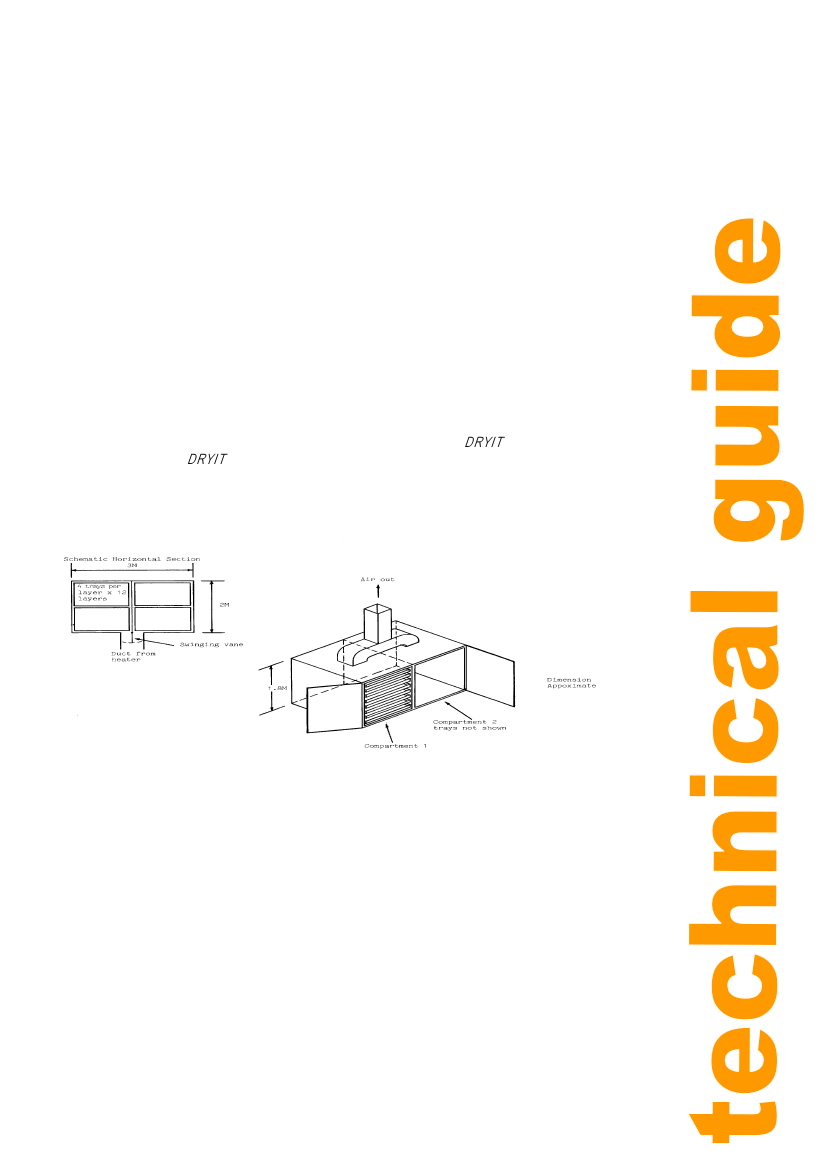

Figure 2: Batch dryer, showing compartments

5